Sustainability

Balmuir's Product Philosophy

We create future classics while respecting life

Sustainability plays an important role in Balmuir's strategy, vision and values.

Balmuir was born out of an admiration for the craft tradition, high-quality natural materials and long-lasting classic designs. Thus, our collection and sustainability-related work have also been shaped by these elements.

Our products are designed in Helsinki, Finland, and they have been awarded the Design from Finland label. One of the most important principles on which our designs are based is cherishing a long service life. For example, our new collections have been designed in such a way that they fit together with our previous collections, making it easy to combine garments to create different ensembles. Over 50% of our line is made up of products that we continue to offer year after year. In fact, several of our products have been in our collection since the company was founded.

Emphasis on natural materials

We choose our materials based on their quality and the purpose of the end product. We favour, for example, soft, pure cashmere and long staple cottons. High-quality materials can be identified based on how they feel on the skin: high-quality silk drapes beautifully over the body, and cools you down in warm weather while providing warmth in cool weather, while long staple cottons feel dense and smooth on the skin.

Over 60%* of our textile products are made of monomaterials. This means that they are made of a single material (e.g., 100% cashmere) instead of mixed fibres. This makes it easier to recycle the products, as the materials can be reused as raw material for new garments at the end of their life cycle. The future textile industry will be based on a circular economy, and our aim is to emphasise circular values more in our product design even today.

Some natural materials are problematic from the point of view of animal rights. Balmuir warrants that its products do not contain:

- angora rabbit wool

- cosmetics tested on animals

- endangered exotic skins

- fur

*Based on 2021 figures

Over half of our products are made in Europe

We strive to manufacture as many of our products as possible at a close proximity. The products in our collection whose materials originate from outside of Europe are produced in their country of origin, where local knowledge on their processing methods is the most sophisticated. Focusing production in the countries of origin of the raw materials also minimises additional need for transport, reducing the carbon footprint of the production process.

Over 50% of our products are manufactured in Europe, where the top producing countries are Portugal (16,2%), Lithuania (4,4%), Estonia (8,8 %), Poland (5,8%) and Italy (11,9%). Other important production countries include China (25,5%), the largest producer of cashmere and silk. In addition to the above-mentioned countries, some of our products are also manufactured, for example, in Nepal (12,2%), a country where handicraft traditions are strongly valued, and Turkey (3,4%).*

Balmuir has around 50 manufacturing partners. We value long-term partnerships. More than 30% of our manufacturers been with us since the company was founded. We require that all our partners adhere to our ethical operating principles.

*Based on 2023 figures

Sustainability and its improvement are part of our daily work

Sustainability has been taken into account in all Balmuir’s activities since the company was founded. We know that sustainability must be based on continuous improvement, and thus, since 2020, we have been developing our sustainability performance more systematically.

Balmuir's sustainability strategy is based on the United Nation’s sustainable development goals, focused on decent work and economic growth, sustainable manufacture, innovations and infrastructures, as well as sustainable consumption and production. Based on these goals, we have increased the use of certified materials and transparency in our production chain, for example. Another of our goals is that the rest of our Chinese manufacturers undergo a social responsibility audit carried out by an independent third party.

We are also focused on improving our maintenance and repair services aimed at extending the service life of our products. In the summer of 2022, we launched the Balmuir Care Spa maintenance service at the Balmuir Brand Store in Helsinki. The Balmuir Care Spa service offers maintenance of Balmuir products. We have switched to using only plastic-free, FSC-certified and recyclable paper-based materials in our shopping bags and gift packaging. We are also developing ways to reduce the use of plastic with our partners who package our products during the manufacturing phase.

We want to act more responsibly and create future classic designs while respecting life.

Balmuir’s carbon footprint

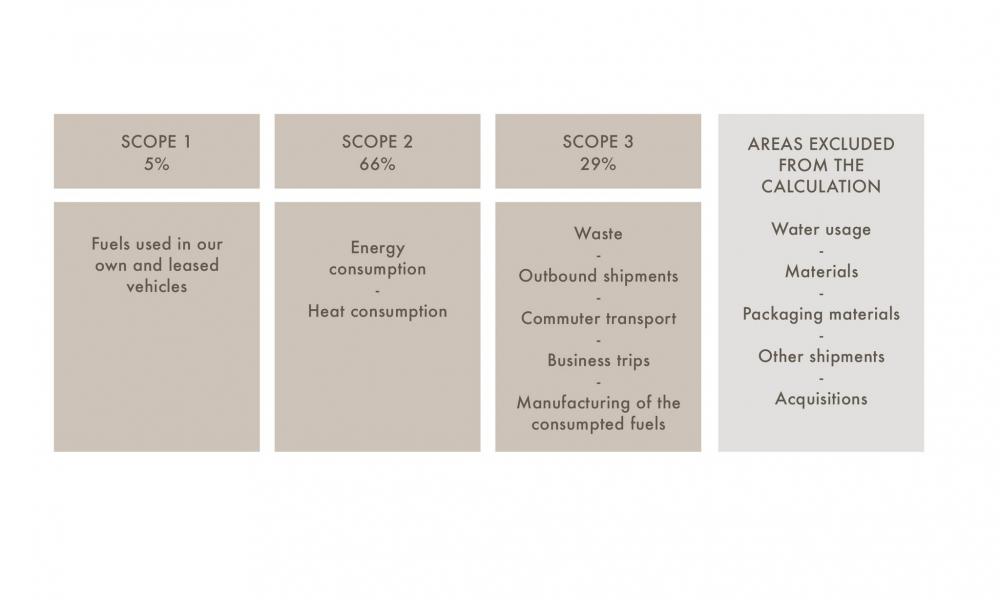

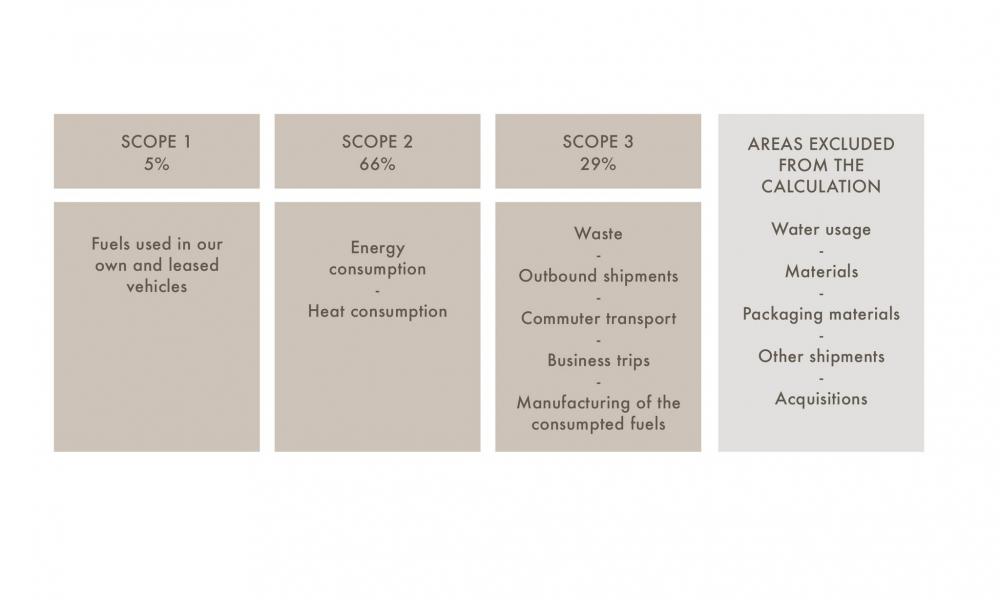

Balmuir’s first step in analysing the company’s emissions and setting targets for their reduction was to calculate the emissions produced by Balmuir’s operations in Finland during 2021. In the deployed calculation method, the emissions from the company’s own activities included scope 1, 2, and 3 emissions, excluding product manufacturing.

In the first part of the calculation, we determined Balmuir’s scope 1 and 2 emissions, which came up to 88.2 t CO2e. Sources of scope 3 emissions included transportation, travel, waste and spent fuel. Used materials, packaging materials, other transport, water and other purchases were excluded from the calculation at this point, to be analysed in the second step of the calculation.

Balmuir has relocated to new premises during years 2022-2023, which has enabled the use of green energy. Balmuir's goal was for its Finnish manufacturing operations to be completely carbon neutral by 2023. This target has been revised and the new target is set on being completely carbon neutral by 2025.

We work continuously to achieve our goals by utilising renewable energy and heating sources, and by updating company’s car and commute policy. The residue emissions are planned to be compensated. Our aim is to calculate emissions comprehensively from scope 3 on a global level by year 2025.